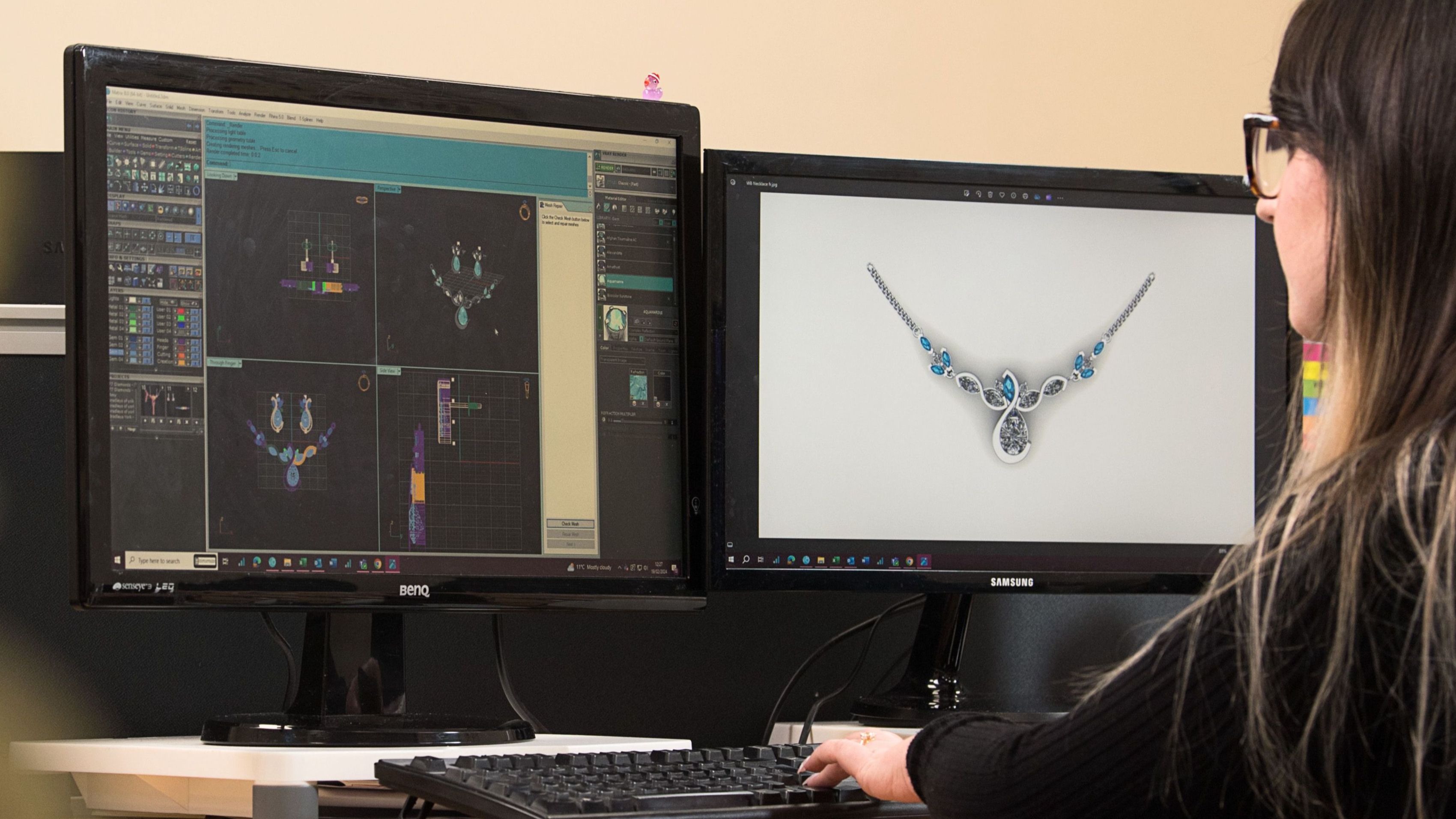

Expert CAD Designers in the Heart of the Jewellery Quarter

Our expert CAD designers will collaborate with you to refine your vision and solve any potential challenges before manufacturing begins, allowing you to present the highest quality product to your customer.

Part of our end-to-end solutions, the right CAD helps guarantee a precise stone fit and a flawless final product before it even leaves the digital realm. By working with us, you're not just getting a file; you're initiating a controlled, efficient, and comprehensive production process that moves seamlessly from CAD to casting, finishing, and hallmarking, all under one roof.

Get in touchWhy Use Weston Beamor for Jewellery CAD Models?

Unrivalled Expertise

Our experienced in-house CAD designers offer a collaborative approach, providing guidance from the outset regardless of your technical knowledge.

Integrated Flexibility

Our CAD services are designed to accommodate your workflow: whether you provide your own files, choose to modify one of your existing designs, or develop a unique creation from scratch.

Fast, Scalable Production

Our integrated CAD services work seamlessly with our in-house manufacturing facility, enabling a faster, more adaptable, and more efficient production timeline.

Cost-Efficiency

With all services handled under one roof, we minimise touchpoints and reduce administrative overhead, ensuring your project moves forward without unnecessary delays or costs.

Service and Collaboration

From initial concept to final production, our team is committed to supporting you every step of the way, ensuring a smooth and successful project collaboration that results in exceptional jewellery for your customers.

Talk to us

Our team is here to help, whether you’re refining an idea or ready to start production, we’ll guide you with expert support.

From Concept to Creation: Our Integrated CAD Process

Our in-house jewellery CAD modelling process creates highly detailed 2D visuals and 3D renders, allowing you and your customer to see and refine your designs before you commit to production. This virtual prototyping gives you a closer evaluation of the piece before it proceeds to casting, ensuring that every design is structurally sound and perfectly suitable for manufacturing.

Working in collaboration, our in-house CAD specialists support you and your customer to refine your design, ensuring both manufacturability and visual accuracy. Once you approve the models, they are 3D printed in resin or wax before proceeding directly to our casting team.

This integrated process enables you to assess virtual models to ensure the design is perfect before we move to production. All final stages—including polishing, setting, and hallmarking—are completed on-site by our expert team and Sub-Assay office, providing comprehensive quality control from start to finish.

Getting Started Is Simple

- Get in Touch: From the very beginning of your project, we help you refine your ideas, consider your options, and plan your piece - all of which we can complete in-house.

- Submit Your Design: Share your sketches, images, scans or even a detailed concept. Our team can create hand-drawn sketches, or review your project and provide a clear, competitive quote.

- Collaborate & Refine: Our CAD specialists will work with you to perfect the design, ensuring every detail is to your liking and is fully manufacturable.

- Approve Your Model: You will receive high-resolution renders and technical drawings for your final approval before we proceed to physical prototyping or production.

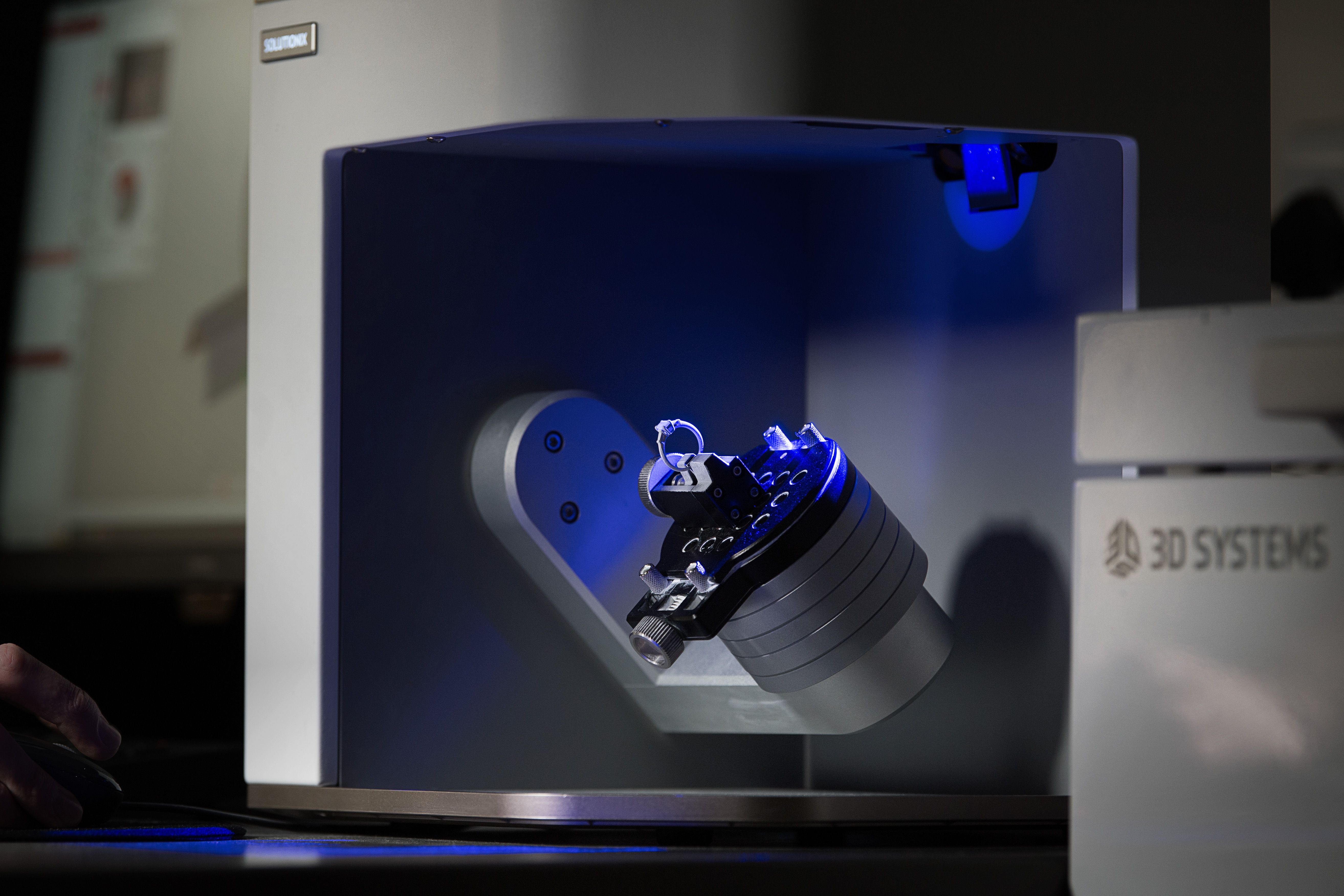

- From Screen to Reality: With your approval, your jewellery CAD model is 3D printed in resin or wax, before moving directly into our in-house production workflow for casting, finishing, and hallmarking.

Our Jewellery CAD Software and Technology

We utilise industry-leading CAD software to ensure every design is crafted with precision and detail. Our commitment to using the most advanced technology in the jewellery industry ensures that your models are not only appealing to your customers but also optimised for seamless integration with our state-of-the-art manufacturing equipment.

Discover Our Full Range of Services

Beyond our CAD services, Weston Beamor offers a comprehensive suite of services to support your jewellery production needs, from initial concept to final hallmark:

- Design: Bring the vision for your bespoke and full ranges to life with our expert jewellery design services, from initial sketches to full 3D renderings.

- 3D Scanning: Accurately replicate existing pieces or physical models into digital files for further modification or reproduction.

- 3D Printing: Rapidly create highly detailed prototypes and master patterns in a variety of materials using cutting-edge additive manufacturing.

- Casting: Utilise our extensive casting facilities for high-quality metal casting in gold, silver, platinum and brass.

- Manufacturing: Benefit from our extensive manufacturing capabilities, turning your designs into tangible, high-quality jewellery pieces.

- Production: From one-offs and small batches to complete ranges, our efficient production processes ensure consistent quality and timely delivery.

- Finishing: Whether you’re after a high-shine polish, a satin texture or something more specialist, we apply care, consistency, and attention to detail.

- Hallmarking: As Weston Beamor customer you can take advantage of our on-site suboffice provided by Birmingham assay office when you cast with us.

Our Services

Bring your vision to life with Weston Beamor.

Ready to Create Your Jewellery CAD Model? Get in touch today to create the digital foundation for your next piece.

Get in touchFAQ’s

What is CAD Modelling?

CAD modelling is the process of creating a 3D digital version of a jewellery design.

What file format will I receive?

You’ll receive an STL file, plus rendered images and 2D visuals.

Can I prototype before production?

Yes, we offer virtual and physical prototyping.

How long does jewellery CAD modelling take?

Most models are completed in a few working days.

Is it possible to modify an existing piece of jewellery?

Absolutely. We can create a CAD model from a physical piece of jewellery, allowing you to easily alter the design, scale it, or add new elements.

Can I provide my own design sketches?

Yes, we can work from a wide range of source materials, including hand-drawn sketches, technical drawings, reference images, or even just an idea.

What if I don't have a design?

No problem. Our in-house designers can work with you to develop a unique design from scratch, providing expert guidance and creative input to bring your concept to life.

What is the difference between a CAD model and a 3D render?

A CAD model is the digital file itself, containing all the geometric data for the design. A 3D render is a photorealistic image or video created from that model, used for marketing, client approvals, and visual presentations.